A spine prepared to last, a binding built to tell a story.

Sewn binding FILO-REFE

Sewn binding FILO-REFE

Perfect binding is the most common type of binding, used in many volumes, but this does not necessarily make it simple or less demanding. The glue is applied to the spine of the previously sewn book.

Sewn perfect binding offers that extra level of sturdiness appreciated especially in volumes intended for frequent use or long life.

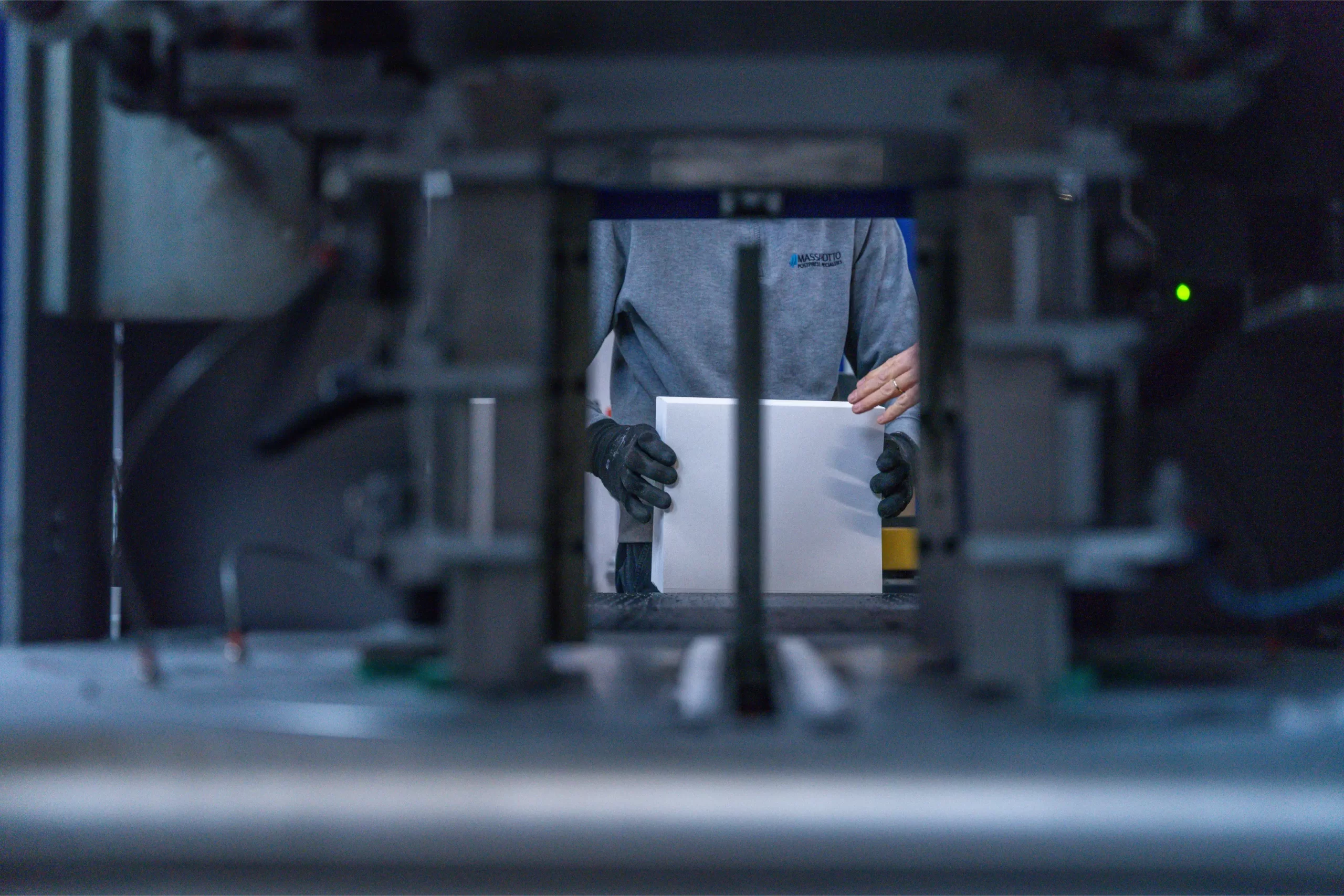

Industrial control + craftsmanship

In the innovative process, we use digital controls that automatically and precisely regulate temperature, pressure, and drying times, ensuring consistency even on large print runs. The combination of industrial strength and artisanal care emerges in every glued spine: a structure that holds pages and reader together, volume after volume.

It is a binding that combines the speed and reliability of large-scale production with the attention to detail typical of high-quality workmanship. The result is a book that not only opens and closes well but also withstands the test of time, maintaining shape and functionality even with repeated use.

Each service can be completed with assembly and finishing, with both bulk PVC and single PVC processing.

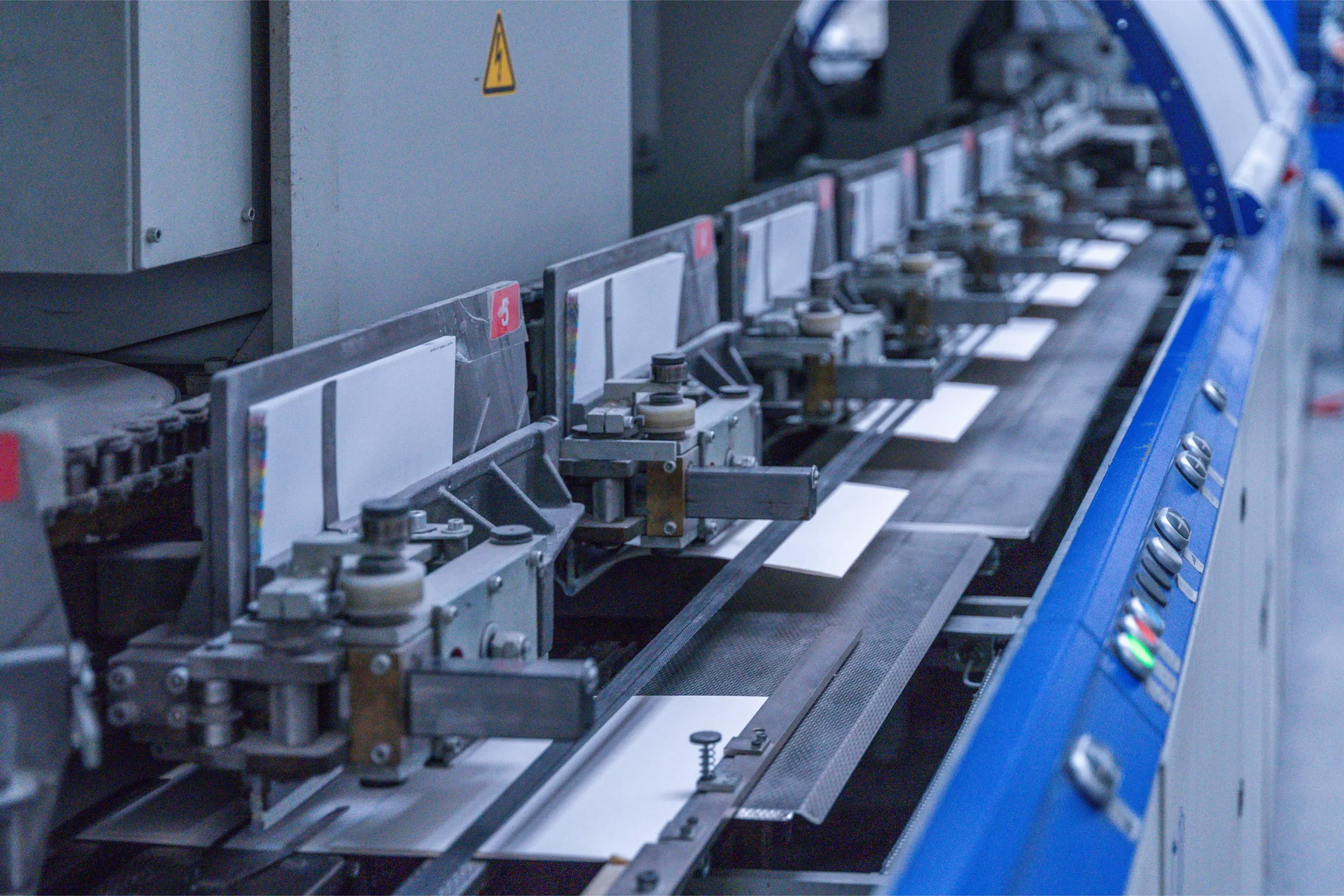

Department equipment

Our perfect binding department has 3 mechanotechnical sewing lines, 2 Kolbus perfect binding lines for volumes with and without flaps with a maximum format of 320x430cm, allowable thickness up to 70mm. The system can use either PUR or EVA glue.

What are the advantages?

Perfect binding ensures compact and durable volumes, keeping the book’s structure stable over time. Precision in glue application or spine milling ensures deep and uniform adhesion, preserving the continuity of the pages. Each process is adapted to the type of booklet and the intended use, making the volume more reliable, more manageable, and more pleasant to consult.